In the vast and ever-evolving world of electrical infra […]

In the vast and ever-evolving world of electrical infrastructure, cable insulation materials play a pivotal role in ensuring safety, efficiency, and reliability. These innovative materials, designed to protect conductors and prevent electrical leakage, have undergone significant advancements in recent years, revolutionizing the way we transmit and distribute electricity.

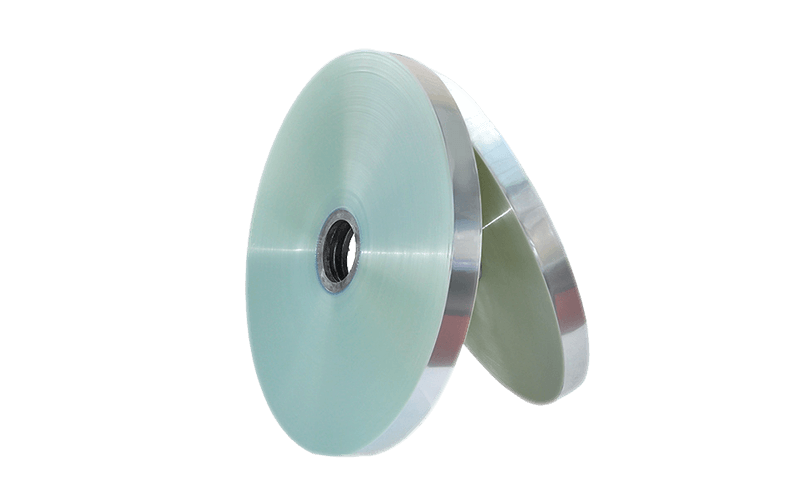

Cable insulation materials are an integral component of electrical cables, acting as a protective barrier between conductors and surrounding environments. Their primary purpose is to prevent current leakage and maintain the integrity of the electrical system. Over the years, various insulation materials have been developed, each offering unique properties to meet different requirements.

One of the most commonly used cable insulation materials is PVC (polyvinyl chloride). PVC insulation is widely recognized for its durability, flexibility, and cost-effectiveness. Its exceptional electrical properties make it suitable for a wide range of applications, including power cables, communication cables, and building wires. PVC insulation provides excellent resistance to moisture, chemicals, and UV radiation, ensuring a long lifespan and reliable electrical performance.

Another popular cable insulation material is XLPE (cross-linked polyethylene). XLPE insulation is highly sought after for its superior electrical properties, including high insulation resistance and low dielectric loss. Its excellent thermal properties enable it to withstand high temperatures, making it a preferred choice for underground power transmission and distribution cables. Moreover, XLPE insulation offers enhanced mechanical strength and resistance against moisture, ensuring reliable and long-lasting cable performance.

For more specialized and demanding applications, cable insulation materials such as EPR (Ethylene Propylene Rubber), silicone rubber, and fluoropolymers are commonly used. EPR insulation provides excellent resistance to heat, ozone, and aging, making it suitable for high-voltage cables and subsea applications. Silicone rubber insulation, known for its flexibility and high-temperature resistance, is often used in high-temperature environments and where flame retardancy is essential. Fluoropolymers, such as PTFE (polytetrafluoroethylene) and FEP (fluorinated ethylene propylene), are valued for their exceptional chemical resistance, high thermal stability, and low friction properties, making them ideal for applications involving harsh environments, chemicals, and extreme temperatures.

Furthermore, eco-friendly and sustainable insulation materials have emerged as a response to growing environmental concerns. Materials such as bio-based polymers made from renewable resources and recyclable insulation options are becoming more prevalent as industries strive for greener and more sustainable solutions.

The constant evolution of cable insulation materials has revolutionized the electrical industry, enabling higher energy transmission capacities, improved safety standards, and reduced environmental impact. Through extensive research and development efforts, manufacturers continue working towards creating materials that offer superior performance, longevity, and efficiency.