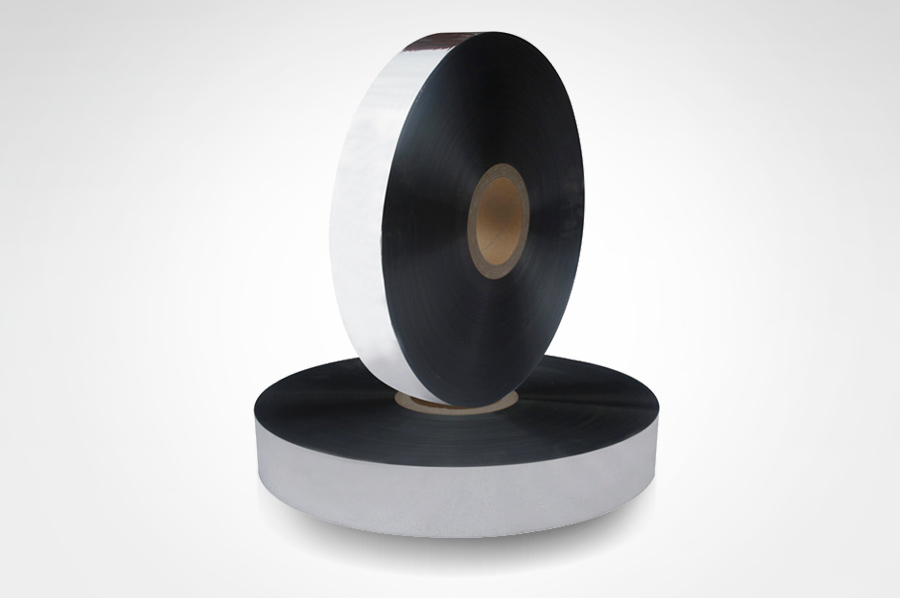

Biaxially stretched Metalized film is made of bright ma […]

Biaxially stretched Metalized film is made of bright materials. BOPET film has the characteristics of high strength, good rigidity, transparency, high gloss, etc .; odorless, tasteless, colorless, non-toxic, outstanding strength and toughness; its tensile strength is 3 times that of PC film and nylon film, and the impact strength is BOPP times the film, with excellent wear resistance, folding resistance, pinhole resistance and tear resistance; the heat shrinkage is extremely small, at 120 ℃, only shrink 1.25% after 15 minutes; Good antistatic property, easy to vacuum aluminize, can be coated with PVDC, thereby improving its heat sealability, barrier property and printing adhesion; BOPET also has good heat resistance, excellent cooking resistance, low temperature freezing resistance Property, good oil resistance and chemical resistance.

With the exception of nitrobenzene, chloroform, and benzyl alcohol, most of the BOPET film cannot dissolve it. However, BOPET will be corroded by strong alkali, so please pay attention when using it. BOPET film has low water absorption rate, good water resistance, and is suitable for packaging food with high water content.Uniaxially stretched polyester film (referred to as CPET for short is a film made of semi-dulling material (added titanium dioxide to raw material polyester chips), dried, melted, extruded, cast and longitudinally stretched. The film has the lowest grade and price, and is mainly used for pharmaceutical tablet packaging. Due to less usage, manufacturers have less large-scale production, accounting for about 5% of the polyester film field, Chinese enterprises also import less, the standard thickness is 150μm. Due to the characteristics of polyester film determines its different uses.

Polyester films for different purposes have different requirements for raw materials and additives, as well as processing techniques, and their thickness and technical indicators are also different; in addition, only BOPET has multiple uses, so the films classified according to use are BOPET. Can be divided into the following types: Electrical insulating film. Because of its good electrical, mechanical, thermal and chemical inertness, good insulation performance and high breakdown voltage, it is dedicated to electronic and electrical insulation materials. Common standard thicknesses are: 25μm, 36μm, 40μm, 48μm, 50μm, 70μm, 75μm, 80μm, 100μm and 125μm micrometer. Including wire and cable insulation film thickness 25-75μm and touch switch insulation film (50-75μm).Capacitive film. It has the characteristics of high tensile strength, high dielectric constant, low loss factor, good thickness uniformity, good electrical performance, and large resistance. It has been widely used in capacitor dielectrics and insulating interlayers.

Commonly used standard thicknesses are 3.5μm, 3.8μm, 4μm, 4.3μm, 4.8μm, 5μm, 6μm, 8μm, 9μm, 9.8μm, 10μm, 12μm.Card protection film. It has good transparency, high stiffness, good thermal stability, excellent surface winding performance, uniform cable insulation material vertical and horizontal tensile properties, and has excellent properties such as waterproof, oil and chemical resistance. It is specially used for the protective packaging of pictures, certificates, documents and office supplies, making it smooth and beautiful after hot stamping as a protective film, which can keep the originals clear and non-deformed. Commonly used standard thicknesses are 10.75μm, 12μm, 15μm, 25μm, 28μm, 30μm, 36μm, 45μm, 55μm, 65μm, 70μm, of which 15μm or more are mainly used as laser anti-counterfeiting base film or high-grade protective film.Universal membrane. With excellent strength and dimensional stability, cold resistance and chemical stability, it is widely used in various substrates such as composite packaging, photosensitive film, metal evaporation, audio and video recording.