Classification according to the materials and productio […]

Classification according to the materials and production process used to produce polyester film

According to the raw materials and stretching process used in the production of Metalized film, it can be divided into the following two types:

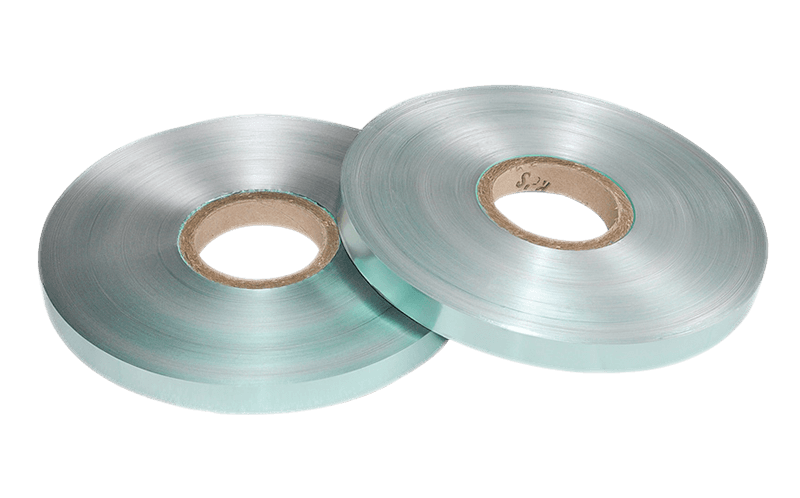

Heat sealing single side 9AL/23PET/3PVC for cable

Place of Origin:Zhejiang, China

Model Number:DX201010-19

Material:AL & PET& PVC

Rated Voltage:10kv

Product name:hot melting aluminum pet mylar tape

Quality:Grade A

Exhibition:Home and abroad

Product Laminating Line:Over 4 lines

District:Lin'an ,Hangzhou ,China

Brand Name:Dongxing

Type:Insulation Tape

Application:High Temperature

Tensile Strength:>20%

Supplier Feature:manufacturer

Originate time of factory:Year at 1992

Yearly output:Over 5000 Tons

Product Cutting Line:Over 4 lines

1. Biaxially oriented polyester film (BOPET for short) is made of glossy material (also known as large glossy material, that is, the content of titanium dioxide in raw polyester chips is 0.1% [1], after drying, melting, extrusion, cast sheet and high-grade film stretched vertically and horizontally, for a wide range of uses). BOPET film has the characteristics of high strength, good rigidity, transparency, and high gloss; it is odorless, tasteless, colorless, non-toxic, and outstanding toughness; its tensile strength is 3 times that of PC film and nylon film, and its impact strength is BOPP 3-5 times that of the film, with excellent wear resistance, folding resistance, pinhole resistance and tear resistance, etc.; heat shrinkage is extremely small, at 120 ° C, only shrinks 1.25% after 15 minutes; has Good antistatic property, easy to carry out vacuum aluminum plating, can be coated with PVDC, so as to improve its heat sealing, barrier and printing adhesion; BOPET also has good heat resistance, excellent cooking resistance, low temperature freezing resistance resistance, good oil resistance and chemical resistance, etc. Except for nitrobenzene, chloroform, and benzyl alcohol, BOPET film cannot be dissolved by most chemicals. However, BOPET will be corroded by strong alkali, so care should be taken when using it. BOPET film has low water absorption and good water resistance, and is suitable for packaging foods with high water content.

2. Uniaxially stretched polyester film (CPET for short) is a film made of semi-dull material (titanium dioxide is added to the raw material polyester chips), dried, melted, extruded, cast and stretched longitudinally. The grade and price are the lowest among films, and are mainly used for pharmaceutical tablet packaging. Due to the small amount of use, manufacturers seldom produce on a large scale, accounting for about 5% of the polyester film field. Chinese companies also seldom import it, and the standard thickness is 150 μm.

Classification according to the use of polyester film

Due to the characteristics of polyester film, its different uses are determined. Polyester films for different purposes have different requirements for raw materials and additives as well as processing technology, and their thickness and technical indicators are also different; in addition, only BOPET has multiple uses, so the films classified according to uses are all BOPET. Can be divided into the following categories:

1. Electrical insulating film. Because of its good electrical, mechanical, thermal and chemical inertness, good insulation performance and high breakdown voltage, it is specially used for electronic and electrical insulation materials. The commonly used standard thicknesses are: 25μm, 36μm, 40μm, 48μm, 50μm, 70μm, 75μm, 80μm, 100μm and 125μm (microns). These include wire and cable insulation film (thickness 25-75μm) and touch switch insulation film (50-75μm).

2. Capacitive film. It has the characteristics of high tensile strength, high dielectric constant, low loss factor, good thickness uniformity, good electrical properties, and high resistance. It has been widely used in capacitor dielectrics and insulating interlayers. Commonly used standard thicknesses are 3.5 μm, 3.8 μm, 4 μm, 4.3 μm, 4.8 μm, 5 μm, 6 μm, 8 μm, 9 μm, 9.8 μm, 10 μm, 12 μm.

3. Card protection film. It has good transparency, high stiffness, good thermal stability, smooth surface, excellent winding performance, uniform vertical and horizontal stretching performance, and has excellent performances such as waterproof, oil-proof and chemical-proof. It is specially used for the protective packaging of pictures, certificates, documents and office supplies, making it flat and beautiful after hot stamping as a protective film, and can keep the original clear and undistorted. Commonly used standard thicknesses are 10.75 μm, 12 μm, 15 μm, 25 μm, 28 μm, 30 μm, 36 μm, 45 μm, 55 μm, 65 μm, 70 μm, among which the thickness above 15 μm is mainly used as laser anti-counterfeiting base film or high-grade protective card film.