In its simplest terms, Metalized film is a plastic that […]

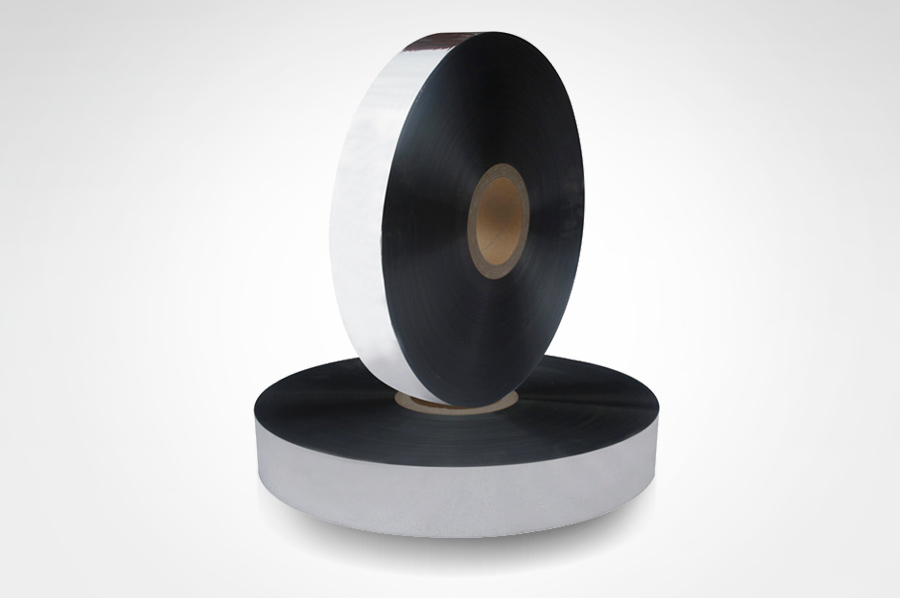

In its simplest terms, Metalized film is a plastic that has been coated with aluminum. This is a popular coating material for packaging as it keeps oxygen, moisture and other contaminants out. It also helps food products retain their color, flavor and aroma, thus increasing their shelf life and decreasing food waste. This type of film is also used in electronics to protect delicate circuits.

It is important to know exactly what metals are contained in a particular metalized film because this can greatly impact recyclability. For example, if a metalized film contains 18% aluminum it will be more likely to be recycled for its aluminum content rather than its plastic, while films that contain less than this amount are more likely to be recycled for their plastic.

Metalized films can be manufactured in many different ways, including as single-layer or bi-layered constructions, which are used to create a variety of finishes. They are available in a range of thicknesses, colors, and alloys, and may contain anti-static agents, UV inhibitors, or other additives. In addition, they can be printed, laminated, or coated with adhesives to provide added functionality and appeal.

Some common examples of this film include Mylar balloons, anti-static bags (the sleeves that new computer components come in) and a variety of thicker snacks, coffee and candy packages. It is also commonly used in the printing industry as a shiny foil, and for decorative purposes in the retail and commercial industries.

The global market for metallized films is expected to expand at a CAGR of 4.3% over the forecast period, from a valuation of US$ 2.10 billion in 2017 to US$ 3.72 billion by 2032. This growth is mainly driven by increased use of the product in packaging, as well as rising technological advancements across the globe.

The market can be segmented based on end users, with packaging holding the largest share in the overall market. This is primarily due to the fact that metallized film is a highly effective barrier against oxygen, moisture and other contaminants, thereby increasing the shelf life of packaged foods. This in turn, reduces food wastage and increases the profitability of the packaging industry.