The most common use for PET mylar is in food packaging, […]

The most common use for PET mylar is in food packaging, where it helps to protect packaged foods from contaminants and other threats. It is also popular in electrical insulation and solar technology. It has great strength, and can withstand very high temperatures without changing form or texture. Additionally, it is more resistant to gases and aromas than other plastic films.

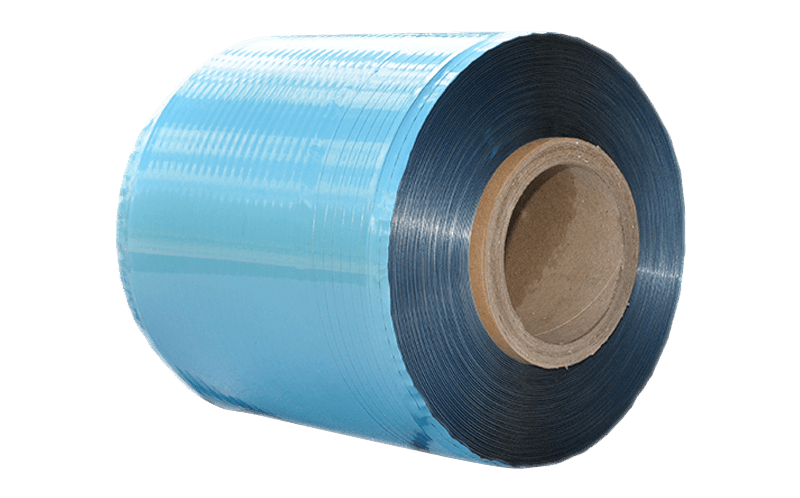

Mylar is a trademark name for a specific type of polyester film, but it is also used to describe a type of plastic sheeting in general. It is a transparent film that has an extremely high-tensile strength and good solvent resistance, chemical and dimensional stability, and excellent transparency. Mylar is available in various gauges, from thin to very thick, and it can be customized with different surface treatments for improved adhesion and printability.

Mylar is made by drawing molten polyethylene terephthalate on a chilled surface, using special machinery that pulls it biaxially. The machine draws it first in one direction and then in the transverse direction, keeping it under tension. It is then chilled again, and the process is repeated several times. This produces a film that is extremely clear with a glossy finish.

The most commonly used gauges of Mylar are 48 and 92 gauge (1mil). Optically clear Mylar is the standard industry grade, but it is also used for electronic and graphic applications. Metallic-metalized Mylar is similar, but it has a shiny silver finish that can reflect light and is used to make overlays for artist projects.

While both normal and aluminized Mylar are plastics, foil is not a plastic. It is a thin layer of aluminum on top of another type of plastic, usually a plastic like PE or PP. Foil is more flexible than Mylar, but it does not have the same tensile strength or chemical resistance.

Aluminized Mylar is actually a type of BoPET film that has been coated with a thin layer of metal, typically aluminum. This coating gives it the appearance of foil but with better mechanical properties, transparency, and oxygen barrier characteristics. It is an excellent alternative to traditional aluminum foil for food packaging, as it is much less expensive and offers the same barrier properties.

There are many other uses for Mylar, including storing emergency food and displaying coins or jewelry in an exhibit. It can also be used to create a protective overlay for maps, charts, and other types of artwork that need protection from chemicals and moisture. It is also useful in electronics, where it can be used to cover delicate components. In fishing, metallized Mylar is sometimes wound around the hook of a fishing rod to give it a reflective striping that can attract fish.